hydraulic color coated corrugated steel floor tile and tiling roll forming making machine

Basic Info

Model No.: FDYX25-205-1025

Product Description

Specifications Good quality

Comprehensive sevice

Good price

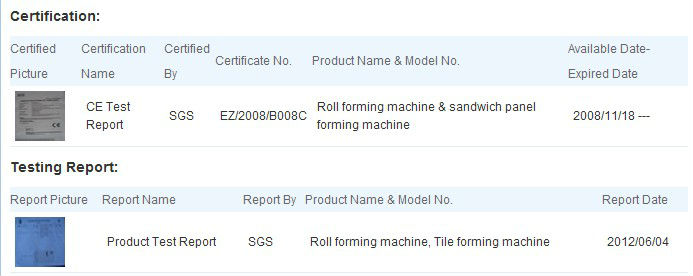

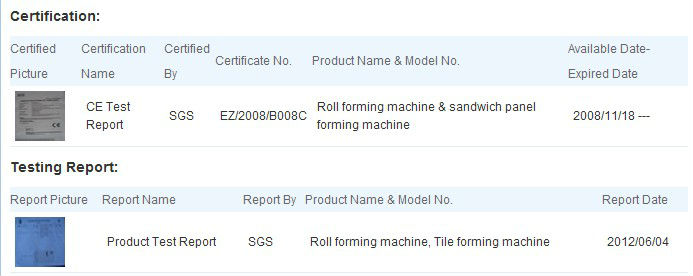

CE certificate

20 years experience

Machine 's components: uncoiler and its base coil sheet guiding dajusting device roll forming system punching system hydraulic post cutting system PLC control system run out table Main technical parameters:

Our advantages :

Machine 's photo:

Product 's sample:

Product 's sample:

Photo of other components: uncoiler:

Photo of other components: uncoiler:  PlC control :

PlC control :  simple run out table:

simple run out table:  Container photo:

Container photo:

our customer:

our customer:

We have developed more than 20 series of steel roll forming machines which can meet the requirements of all steel constructions, such as production lines for wall & roof sheet, color steel tile, C & Z & W shape purlin and floor decking sheet as well as production line for all kinds of sandwich panels, curving machine for roof sheets. We also supply production lines of guardrail sheet for expressway, shutter doors, garages doors and downpipe. Besides, we devoted ourselves to the research & development of various kinds of other products related to steel structure, such as Hydraulic Press Brake Machine, shearing machine, slitting machine, etc. If you have interesting please do not hesitate to contact me. Contact us if you need more details on Hydraulic Tiling Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Floor Tile Roll Forming Machine、Corrugated Steel tile forming machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

We have developed more than 20 series of steel roll forming machines which can meet the requirements of all steel constructions, such as production lines for wall & roof sheet, color steel tile, C & Z & W shape purlin and floor decking sheet as well as production line for all kinds of sandwich panels, curving machine for roof sheets. We also supply production lines of guardrail sheet for expressway, shutter doors, garages doors and downpipe. Besides, we devoted ourselves to the research & development of various kinds of other products related to steel structure, such as Hydraulic Press Brake Machine, shearing machine, slitting machine, etc. If you have interesting please do not hesitate to contact me. Contact us if you need more details on Hydraulic Tiling Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Floor Tile Roll Forming Machine、Corrugated Steel tile forming machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Comprehensive sevice

Good price

CE certificate

20 years experience

Machine 's components: uncoiler and its base coil sheet guiding dajusting device roll forming system punching system hydraulic post cutting system PLC control system run out table Main technical parameters:

| Suitable material | color steel sheet or galavanized steel sheet |

| Thickness of raw material | 0.3 ~ 0.8 mm |

| Yield strength of material | 235 Mpa~ 345Mpa |

| Forming speed | 2 ~ 5 m/min |

| Main moto power | 5.5 KW |

| Hydraulic station power | 2.2 KW |

| Uncoiler loading capacity | Max capacity: 5 tons, (can be increased to be 10 tons) |

| Controlling system | Mitsubishi PLC & converter |

| Machine's size | about 10 m * 1.5 m* 1.5m |

|

| our machine | Other company 's machine | Influence of the machine |

| Machine's base | High strength H350 / H400 steel. machine through milling macine after welding. | H270 steel mark, after welding use manual polish. | keep base in the same horizontal line, ensure product standard. |

| roller material | High grade No.45 forged steel, with digital-controlled procession, Plated with 5 um chrome coated | normal No. 20 steel with Simple polished and have no coating | Roller will have longer use life and ensure the products have same size, no nick on the surface. |

| side wall | use high strength16mm thickness steel panel mark | use 12 mm thickness steel panel mark | ensure machine harder to deform, keep the product accurate and stable |

| Active shaft material | High grade solid No.45 carbon steel, Shaft diameter is 72mm. surface CNC polish treatment. | normal No. 45 steel with no surface treatment | improve the integrated mechanic feature of the shaft. and ensure the shaft stability keep product standard. |

| Electrical elements | PLC control panel, transducer imported from Mitsubishi of Japan. Other elements from famous suppliers in China | all the elements are made in china | machine become more accurate and more stable |

| cutter blade | Cr12 mould steel with quenched treatment | normal high strength steel without quenched treatment | stable the integrated mechanic feature of the cutter blade, harder to deform, longer blade's life, ensure product standard. |

Product 's sample:

Product 's sample:

Photo of other components: uncoiler:

Photo of other components: uncoiler:  PlC control :

PlC control :  simple run out table:

simple run out table:  Container photo:

Container photo:

our customer:

our customer:

We have developed more than 20 series of steel roll forming machines which can meet the requirements of all steel constructions, such as production lines for wall & roof sheet, color steel tile, C & Z & W shape purlin and floor decking sheet as well as production line for all kinds of sandwich panels, curving machine for roof sheets. We also supply production lines of guardrail sheet for expressway, shutter doors, garages doors and downpipe. Besides, we devoted ourselves to the research & development of various kinds of other products related to steel structure, such as Hydraulic Press Brake Machine, shearing machine, slitting machine, etc. If you have interesting please do not hesitate to contact me. Contact us if you need more details on Hydraulic Tiling Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Floor Tile Roll Forming Machine、Corrugated Steel tile forming machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

We have developed more than 20 series of steel roll forming machines which can meet the requirements of all steel constructions, such as production lines for wall & roof sheet, color steel tile, C & Z & W shape purlin and floor decking sheet as well as production line for all kinds of sandwich panels, curving machine for roof sheets. We also supply production lines of guardrail sheet for expressway, shutter doors, garages doors and downpipe. Besides, we devoted ourselves to the research & development of various kinds of other products related to steel structure, such as Hydraulic Press Brake Machine, shearing machine, slitting machine, etc. If you have interesting please do not hesitate to contact me. Contact us if you need more details on Hydraulic Tiling Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Floor Tile Roll Forming Machine、Corrugated Steel tile forming machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Steel tile forming machine

Premium Related Products

Other Products

Hot Products

Different profile double wall / roof layer roll formerDown pipe forming machineFloor deck forming machineColored steel sheet forming machineRidge cap forming machinechina metal Slitting Linechina best quality Pu sandwich panel machine lineEmbossing MachineSteel shutter door forming machineBending MachineHigh speed uncoiling-leveling-cut to length-stacking lineHigh Quality Galvanized Steel CoilLIGHT STEEL KEEL FORMING MACHINEu purlin forming machine with punching systemCORRUGATED STEEL SHEETtile sheet forming machine