Technical parameters:

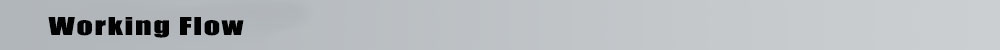

Beading Equipment

a . Speed:10m/min b . Power:2.2kw or according to the profile

c . Diameter of roller:according to the profile d . Power supply:motor

e . Material of roller:quenched and tempered , chrome

Roll Forming Part

a . Frame:Cantilever structure b . Speed:10m/min

c . Power:4kw up, 7.5kw down d . Shaft diameter:50 mm

e . Distance roller head:350mm f . Rollers: 11 up, 18 down

g . Rock wool delivery device h . Motor Power:2*1.5Kw

i . Speed:8m/min j . maximum transport width:1200mm

a . Effective volume:150L b . Unit motor power:10KW

a . Length:10mm b . Width:1200mm

c . Lifting speed:200mm/min d . Drive motor power:2.2Kw*4

e . Lifting motor power:1.5Kw*4 f .Speed:10 m/min

Cutting Part

a . Cutting motor power:7.5Kw b . Lateral movement motor power:1.1 KW

c . Traversing speed:150 mm/s d . Cutting width:1300 mm

e . Cutting error:±2mm

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .

We provide an extensive line of products , including roller shutter door roll forming machine ,door frame machine, roof and wall Panel Roll Forming Machine , Double layer roll forming machine ,floor deck roll forming machine ,C / Z / U Purlin Roll Forming Machine , Stud and Track Roll Forming Machine , ridge cap roll forming machine , downspout pipe roll forming machine , shearing machine and Bending machine , slitting and cutting machine .