Rock Wool Sandwich Panel Roll Forming Machine

Basic Info

Model No.: HKY Rock Wool Sandwich Panel Roll Forming Machine

Product Description

Model NO.: HKY Rock Wool Sandwich Panel Roll Forming Machine Condition: New Usage: Roof, Wall, Floor Max Feeding Width: 1000-1250 mm Thickness of Product: 50mm-250mm Electrical System: PLC&HMI Control System Total Power: 32 Kw Full Automatic: Yes Trademark: HKY Origin: China Certification: SGS, CE, ISO, ISO9001: 2000, CE Customized: Customized Transmission Method: Electric Product Max Effective Width: 760-1120 mm Cutting System: Auto Hydraulic Tracking Cutting System Machine Body: Electrostatic Spraying Treatment Processing Speed: 0-4 M/Min Warranty: 2 Years Specification: Rock Wool Sandwich Panel Roll Forming Machine

Rock Wool Sandwich Panel Roll Forming Machine

We are the professional color steel sheet Cold Roll Forming Machine manufacturer in China.

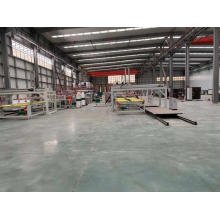

Roll Forming Machine is made of feeding section, forming section and punching & cutting section, the finished profiles are flat and beautiful and high strength and durable. The finished profiles are widely used in construction sites, workshop, warehouses and so on.

Our machine features high durability and good appearance. Welcome to inquiry our machines, we will offer the lower price and better delivery time.

All Quotation Prices are subjected to the HEIGHT / DEPTH (≤ 35 mm) of RIBS (≤ 7 rows).

Product Thickness: 50~250 mm.

Description of Technical Parameters, as follows:

Manual Un-coiler:

Max Capacity: 5000kgs.

Inner diameter of coil: 400-600mm.

Manual with brake.

Leveler Device:

Ensure the material level and straight.

The width can be adjusted.

Main Forming System:

Max Feeding Width: 1000-1250 mm.

Product Max Effective Width: 760-1120 mm.

Thickness of Panel: 0.2-1.0 mm.

Material Type: GI sheet coil or cold rolled coil etc.

Diameter of Main Shaft: 95 mm; Rollers Station: 14 Rows.

Roller Material: C45 steel, Heat Treatment.

Surface of Roller: Chrome plating, Heat Treatment.

Driving Mode: By Chain and Gear Box.

Main Motor Power: 5.5 Kw.

Machine Body: Electrostatic Spraying Treatment.

Thk of Shell frame: 20mm; Base Frame: 350 H steel welded.

Forming Speed: Min. 0-10 m/min.

Install Dimension(L*W*H): 7900mm×1500mm×1400mm.

Gluing System:

The main motor power: 1.5 Kw

The quantity of gluing pump: 2 Sets

Composite Panels Forming System:

Main motor power: 8.5kw

Number of gluing rollers: 49

Install dimension(L*W*H): 10000mm×2200m×2000mm.

Auto Hydraulic Tracking Cutting System:

Cutting Way: Pause to Cutting, Non-stop.

Hydraulic Station Power: 5.5 Kw .

Cutting mould: 3 sets (1 Set for Top Layer, 2 Sets for bottom Layer).

Blade Material: CR12mov with heat treatment HRC60-62.

Install Dimension(L*W*H): 3000mm×2000mm×2000mm.

Auto Elevator System:

Main motor power: 2 Kw.

Electrical System (PLC&HMI Control System):

Electrical System: PLC and HMI touch Screen (Taiwan Delta).

Automatic Measuring Length Function Available: Yes, Rotary Encoder.

Automatic Counting Function Available: Yes.

Current Protection Function Available: Yes, Aviation Plugs.

Voltage: 380V, 50Hz, 3 Phase (as per local requirement).

Run-Out Table:

Frame: 8# steel groove welded.

Roller type.

Quantity: 1 pc.

Total Dimension(L*W): 30000mm×2400mm.

Total Weight: 16 tons.

Total Power: 32 kw.

Processing Speed: 0-4 m/min.

Product Thickness: 50-250 mm.

Annual Output: 600,000.

(They can be modified according to customer requirements)

Service Commitment & Quality Assurance

Installation: If necessary, engineer is available to service machinery overseas; but all the relevant cost and extra 100USD/day for our engineer will be paid by the buyer.

Warranty: 2 years since the machine leave seller's factory.

During the warranty period, it covers all spare parts of machines, if you find some spare parts were damaged, those new spare parts will be supplied free by us, but normal wear and tear excepted. And the freight should be bore equally by both parties.

We will provide the technical support for the whole life of the equipment.

Our Main Machines:

If you have any questions, please let me know them, I will reply you in 24 hours and offer the optimum solution to you.

Please send me your email, and then I will send you Full Selection Machine Catalogues with all parameters of machines and products!

And I can send the Videos of roll forming machines to you, so that you can directly see our machines!!!

WELCOME TO VISIT OUR COMPANY AT ANY TIME!!!!! Contact us if you need more details on Used for Roof or Wall. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Building Material Making Machine、Automatic Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Rock Wool Sandwich Panel Roll Forming Machine

We are the professional color steel sheet Cold Roll Forming Machine manufacturer in China.

Roll Forming Machine is made of feeding section, forming section and punching & cutting section, the finished profiles are flat and beautiful and high strength and durable. The finished profiles are widely used in construction sites, workshop, warehouses and so on.

Our machine features high durability and good appearance. Welcome to inquiry our machines, we will offer the lower price and better delivery time.

All Quotation Prices are subjected to the HEIGHT / DEPTH (≤ 35 mm) of RIBS (≤ 7 rows).

Product Thickness: 50~250 mm.

Description of Technical Parameters, as follows:

Manual Un-coiler:

Max Capacity: 5000kgs.

Inner diameter of coil: 400-600mm.

Manual with brake.

Leveler Device:

Ensure the material level and straight.

The width can be adjusted.

Main Forming System:

Max Feeding Width: 1000-1250 mm.

Product Max Effective Width: 760-1120 mm.

Thickness of Panel: 0.2-1.0 mm.

Material Type: GI sheet coil or cold rolled coil etc.

Diameter of Main Shaft: 95 mm; Rollers Station: 14 Rows.

Roller Material: C45 steel, Heat Treatment.

Surface of Roller: Chrome plating, Heat Treatment.

Driving Mode: By Chain and Gear Box.

Main Motor Power: 5.5 Kw.

Machine Body: Electrostatic Spraying Treatment.

Thk of Shell frame: 20mm; Base Frame: 350 H steel welded.

Forming Speed: Min. 0-10 m/min.

Install Dimension(L*W*H): 7900mm×1500mm×1400mm.

Gluing System:

The main motor power: 1.5 Kw

The quantity of gluing pump: 2 Sets

Composite Panels Forming System:

Main motor power: 8.5kw

Number of gluing rollers: 49

Install dimension(L*W*H): 10000mm×2200m×2000mm.

Auto Hydraulic Tracking Cutting System:

Cutting Way: Pause to Cutting, Non-stop.

Hydraulic Station Power: 5.5 Kw .

Cutting mould: 3 sets (1 Set for Top Layer, 2 Sets for bottom Layer).

Blade Material: CR12mov with heat treatment HRC60-62.

Install Dimension(L*W*H): 3000mm×2000mm×2000mm.

Auto Elevator System:

Main motor power: 2 Kw.

Electrical System (PLC&HMI Control System):

Electrical System: PLC and HMI touch Screen (Taiwan Delta).

Automatic Measuring Length Function Available: Yes, Rotary Encoder.

Automatic Counting Function Available: Yes.

Current Protection Function Available: Yes, Aviation Plugs.

Voltage: 380V, 50Hz, 3 Phase (as per local requirement).

Run-Out Table:

Frame: 8# steel groove welded.

Roller type.

Quantity: 1 pc.

Total Dimension(L*W): 30000mm×2400mm.

Total Weight: 16 tons.

Total Power: 32 kw.

Processing Speed: 0-4 m/min.

Product Thickness: 50-250 mm.

Annual Output: 600,000.

(They can be modified according to customer requirements)

Service Commitment & Quality Assurance

Installation: If necessary, engineer is available to service machinery overseas; but all the relevant cost and extra 100USD/day for our engineer will be paid by the buyer.

Warranty: 2 years since the machine leave seller's factory.

During the warranty period, it covers all spare parts of machines, if you find some spare parts were damaged, those new spare parts will be supplied free by us, but normal wear and tear excepted. And the freight should be bore equally by both parties.

We will provide the technical support for the whole life of the equipment.

Our Main Machines:

| Color Steel Tile Roll Forming Machine | Large-Span No-Girder Roll Forming Machine |

| Glazed Color Steel Tile Roll Forming Machine | Large-Span Curve Forming Machine |

| Double Layer Color Steel Tile Roll Forming Machine | Roller Shutter Door Machine |

| Rock Wool And EPS Sandwich Panel Forming Machine | Door Profile Machine |

| C/Z/U/T Purlin Roll Forming Machine | 4m - 6m Hydraulic Bending Machine & Shearing Machine |

| Light Steel Keel Roll Forming Machine | Auto Crimping Curved Roll Forming Machine |

| Color Steel Roof Ridge Cap Roll Forming Machine | Tooth Shape Corrugated Sheet Bending machine |

| Steel Floor Deck Panel Roll Forming Machine | Hydraulic Full-Automatic De-coiler and Coil Car |

| Wind-Proof And Dust Shield Board Roll Forming Machine | Metal Sheet Foot Pedal Shear Machine |

| Highway Guard Rail Sheet Roll Forming Machine | Flattening Machine |

| Car Carriage Plate Roll Forming Machine | Simple & Heavy Slitting Machine |

| Environmental Anode Steel Plate Roll Forming Machine | New Type Cement Fiber tile forming machine |

If you have any questions, please let me know them, I will reply you in 24 hours and offer the optimum solution to you.

Please send me your email, and then I will send you Full Selection Machine Catalogues with all parameters of machines and products!

And I can send the Videos of roll forming machines to you, so that you can directly see our machines!!!

WELCOME TO VISIT OUR COMPANY AT ANY TIME!!!!! Contact us if you need more details on Used for Roof or Wall. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Building Material Making Machine、Automatic Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Sandwich panel machine

Premium Related Products

Other Products

Hot Products

Different profile double wall / roof layer roll formerDown pipe forming machineFloor deck forming machineColored steel sheet forming machineRidge cap forming machinechina metal Slitting Linechina best quality Pu sandwich panel machine lineEmbossing MachineSteel shutter door forming machineBending MachineHigh speed uncoiling-leveling-cut to length-stacking lineHigh Quality Galvanized Steel CoilLIGHT STEEL KEEL FORMING MACHINEu purlin forming machine with punching systemCORRUGATED STEEL SHEETtile sheet forming machine