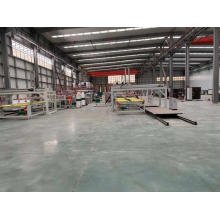

Rockwool Mineral Wool Sandwich Panel Production Machine Line

| Payment Type: | L/C,T/T |

|---|---|

| Terms of Trade: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 45-55 Days |

| Packaging: | 1. Two 40ft container for loading one set machine with manual decoiler; 2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; |

|---|---|

| Productivity: | 40sets Per Month |

| Brand: | JCX |

| Transportation: | Ocean,Land |

| Place of Origin: | Hebei China |

| Supply Ability: | 40sets Per Month |

| Certificate: | CE, ISO, SGS |

| Port: | Tianjin,China |

Basic Info

Model No.: Rockwool Mineral Wool Sandwich Panel Production Machine Line

Click on the follow link to find out more information: https://www.jcxsteelrollformer.com/mineral-wool-sandwich-panel-forming-machine/

Company Info

- Company Name: Botou Golden Integrity Roll Forming Machine Co.,Ltd

- Representative: YANG JIE

- Product/Service: Roof Panel Roll Forming Machine , Cz Purlin Roll Forming Machine , High Way Crash Barrier Roll Forming Machine , Light Gauge Framing Machine , Roller Shutter Door Forming Machine , Double Layer Roll Forming Machine

- Capital (Million US $): 500000RMB

- Year Established: 2010

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 51% - 60%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 15

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 5,000-10,000 square meters

- Factory Location: ECONOMIC DEVELOPMENT ZONE ,BOTOU CITY

- Contact Person: Mr. Jason Zhang

- Tel: 86-318-8189095

Premium Related Products

Other Products

Hot Products

Different profile double wall / roof layer roll formerDown pipe forming machineFloor deck forming machineColored steel sheet forming machineRidge cap forming machinechina metal Slitting Linechina best quality Pu sandwich panel machine lineEmbossing MachineSteel shutter door forming machineBending MachineHigh speed uncoiling-leveling-cut to length-stacking lineHigh Quality Galvanized Steel CoilLIGHT STEEL KEEL FORMING MACHINEu purlin forming machine with punching systemCORRUGATED STEEL SHEETtile sheet forming machine